Pneumatic gripper tube – GGD

The GGD/ GGDA pneumatic gripper

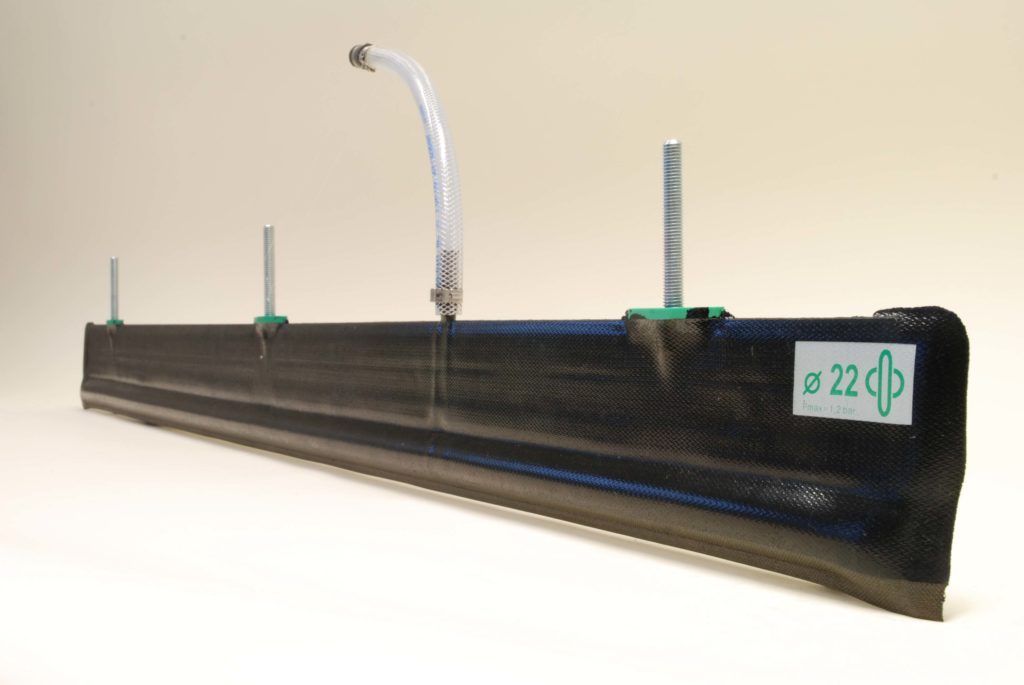

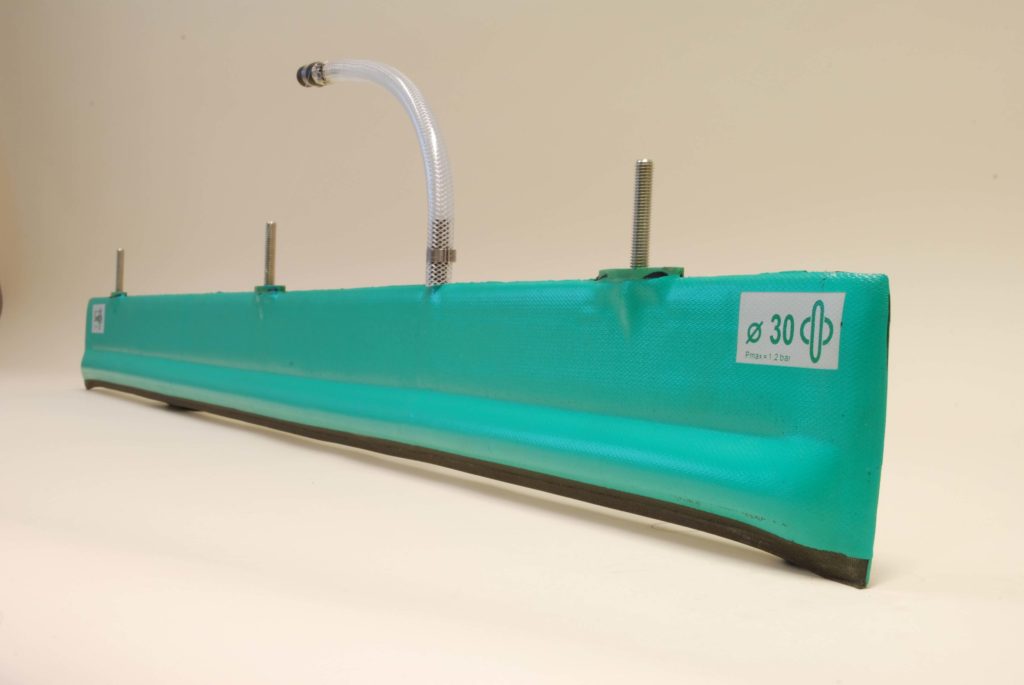

The GGD pneumatic gripper tube is intended for handling short and close-necked bottles. For this purpose, it consists of an inflatable air jack which only inflates in the lower part. This gripper is attached to an automatic or semi-automatic palletizer robot for (de)palletizing glass bottles by layer.

| REF. | ∅ (mm) | H (mm) | E** (mm) |

| GGD12 | 12 | 89 | 8 |

| GGD14 | 14 | 92 | 8 |

| GGD16 | 16 | 94 | 8 |

| GGD18 | 18 | 98 | 8 |

| GGD20 | 20 | 100 | 8 |

| GGD22 | 22 | 102 | 8 |

| GGD25 | 25 | 107 | 8 |

| GGD30 | 30 | 110 | 8 |

| GGD35 | 35 | 129 | 8 |

** Thickness under vacuum.

User / use

Bottling: (De)palletization of bottles

Bottle manufacturers: Palletization of bottles

General industry: (de)palletization of various containers (plastic containers, cardboard containers, hollow glass, PET…)

Technical characteristics

The GGD gripper tube is manufactured with a vulcanised rubber substrate which resists abrasion and withstands high pressures. The maximum recommended operating pressure is 1.2 bar. The standard GGD pneumatic gripper tube is equipped with 3 fasteners positioned 510 mm from the centre fastener and a supply hose with a coupler for connection to a source of compressed air.

The standard length of the GGD gripper is 1340 mm for European pallets and 1470 mm for US pallets.

Performance

The GGD gripper tube has the distinctive feature of having a thickness under vacuum of several millimetres to be able to be inserted between the necks of bottles with a very small footprint. It comes in a “flat” version for small diameters, because it is intended for small format bottles with short and close necks. Several lengths, 1340 mm or 1470 mm, can be supplied with 2 air supplies and different non-standard centre distances. It is equipped with a low fabric reinforcement which gives it better abrasion resistance.

Composition

The GGD pneumatic gripper tube is divided into 3 areas:

- Inflatable body

- 3 attachment points

- 1 inflatable tube equipped with a quick-connect fitting that can be connected to a compressed air source

Customisation

Our engineering office will study the best bottle-picking solution for you. We adapt the length, fastener positioning and supply manifold based on your palletizing head and your process.

As an addition to studying the custom solution, we offer upstream options such as the aluminium profile to stiffen the gripper tubes when handling full bottles, a low fabric reinforcement to limit abrasion on the lower part of the grippers and different centre spacing of the fasteners or of the supply positions. The GGD gripper is available in food contact version certified in accordance with the FDA standard.

Why choose Simtech grippers tubes?

Simplicity of use | Saves time | Saves space | Profitability | adaptable to your installations | production flexibility (grippers for all bottle formats) | Low maintenance

Why choose Simtech quality?

We are manufacturers and ISO 9001: 2015 certified | We have qualified staff | We export our products worldwide

We have more than 25 years experience in our field